The injection molding is one of the most spread process of industrial production with thermoplastic material and it allows to have high levels of productivity keeping the prices low, as long as the preliminary activities for the realization of the product are properly performed. The injection molding allows the production of finished products, namely products that don’t need additional processing and that don’t show complexed geometries. The material is plasticized (melted) and then injected in moldings for the serial production of plastic components. Special attention must be paid to the pressure exerted during the process, to the cycle times and the exportation of heat inside the mold, that are the variants that impact on the quality of the product, the efficiency and consequently on the production costs.

The technological evolution of last years allowed to move from a production with hydraulic presses, started by an hydraulic engine, to the use of new kind of innovative machines: electric engine machines.

These allow to have an higher efficiency, ensuring the maximum precision while printing and conditions of repeatability of the process making it more automated, also there are better conditions of working for the operator (sound emissions are lower) and there are no more pollution issues given by the dispose of the engine oil. For the production of components, Simplastic S.r.l. makes us of 12 injection machines active 24 hours a day for 6 days, able to process different types of plastic material, selected depending on the necessities.

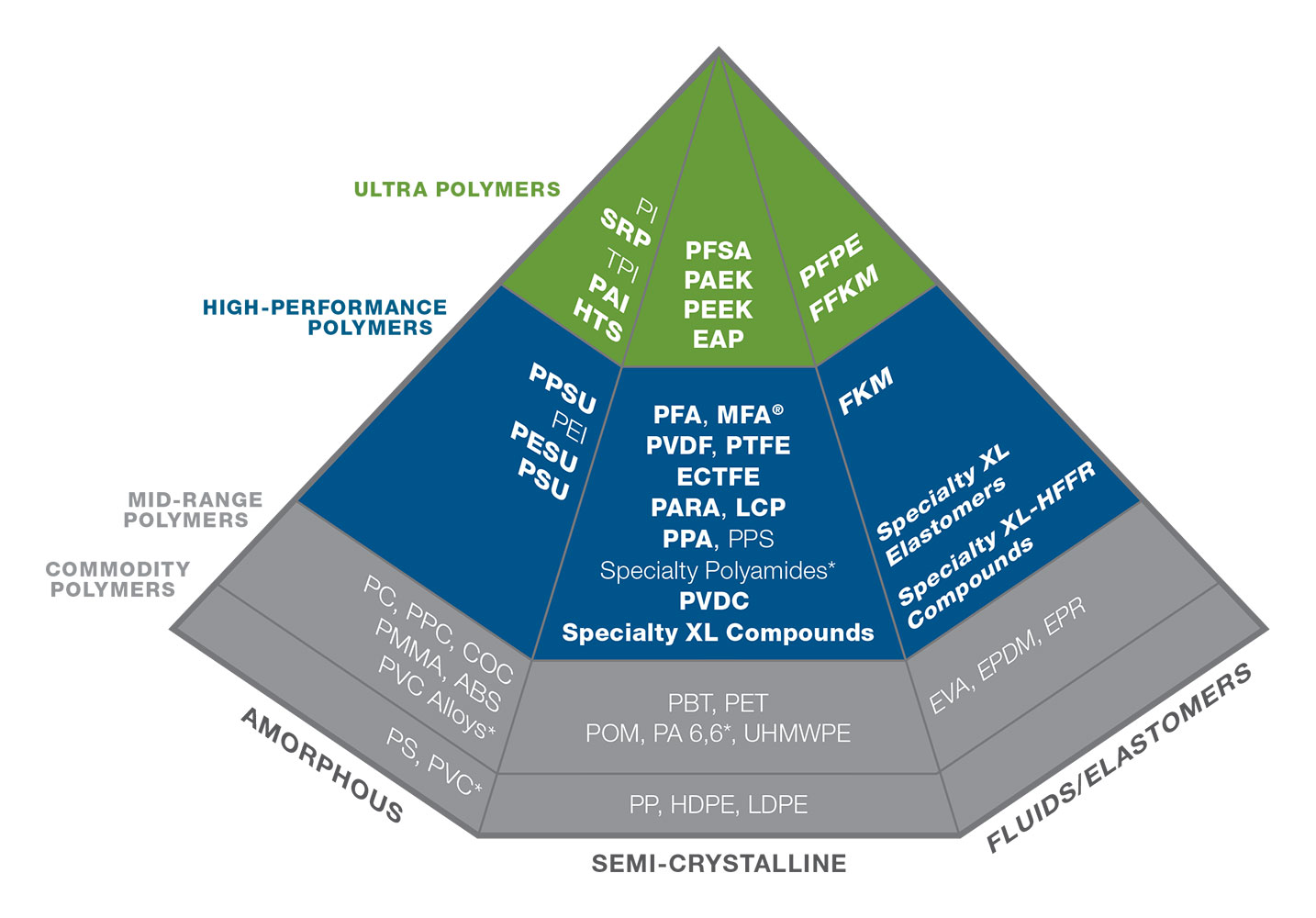

With the injection process more of twenty categories of polymers are processed, from numerous elastomers in substitution of rubber material, to a large group of basic polymers and various high performance superpolymers. The choice of the material, typically analyzed during the design of the mold, considers the mechanical properties, the processability, the esthetical aspect and the cost of the material of the final product. Among the high quality plastic material certified from our suppliers, there are: ABS, ABS/PC, HDPE, LDPE, PBT, PC, POM, PP, PS, TPE/TPV, TPU, PA, PMMA, PVC, PBT-PC, PBT-PET.

Simplastic S.r.l. besides the classic injection molding, can realize processes of overmolding and co-molding. The overmolding injection or printing with insert is a technique of injection molding that requires the melting of thermoplastic material injected in a high resistance steel mold that has inside plastic elements (already produced) or metal elements. The plastic co-molding or plastic co-molding injection is a process that aims to obtain a finished product made by different plastic materials “melted” with incorporated materials or metals. Our Company has developed different techniques to make the co-molding of plastic materials of high quality, reliability, resistance and aesthetic rendering.

The wide tonnage range (65 ton - 270 ton) allows to produce articles of different types, colors, size and weight, giving the company the chance to be active in various sectors, from the automotive to the furniture of schools and offices, fixtures and much more, while the integrated control system in the machines makes sure that the anomalies are immediately identified and corrected following the required parameters.